Cable manufacturing and overmoulding

A cable is still considered the safest and most reliable way to transmit signals and electrical power.

In order to make the use of cables more flexible, to shorten assembly times and to ensure fault-free connections, cables are pre-assembled with plugs. Most of our cables are individual products that are tailored to the special requirements and wishes of our customers.

In order to counteract possible problems (kinking of the cable, ingress of water into the plug, etc.), we also offer the possibility of encapsulating/overmoulding various types of contacts and connectors as required. Existing tools as well as custom fabrication offer numerous possibilities for a safe, watertight and consistent solution.

To give you an insight into our possibilities, you will find here a brief overview of various solutions already implemented.

- 2x AMP Superseal 3-pin

- 1x Junior Timer 2-pin

- 1x German DT Serie 4-pin

- 1x AMP Econoseal J 13-pin

- 10x 0,75mm² cord black

- Molex Minifit, 14-pin, male

- Molex Minifit, 8-pin, female

- Molex Minifit, 2-pin, female

- 4x 0,75mm² chord

- Delphi-Plug, 3-pin, IP67

- 6.3 x 0.8 blade receptacle

- FLYF 25mm² cable red

- ITT Cannon APD plug

- M8 cable lug

- 6x 0,5mm² cable according to DIN 47100

- TE Econoseal plug 13-pin

- M16 cable gland

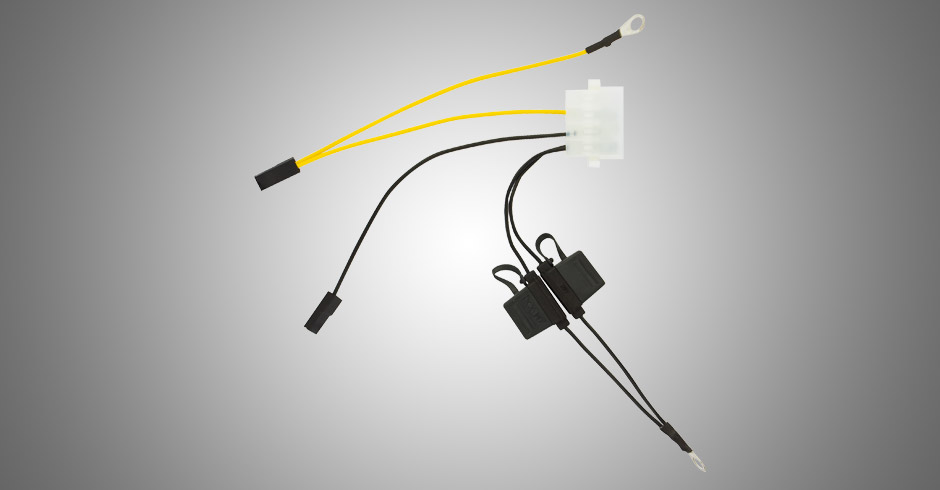

- 2x 1,5mm² cord

- 2x fuse holder with M8 cable lug

- 3x 1mm² cord

- 2x 6.3 x 0.8 blade receptacle

- 2x M8 cable lug

- Molex Minifit, 8-pin