Casting process

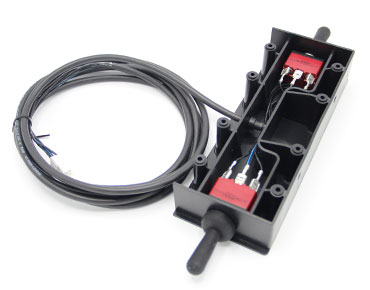

The casting process is the procedure, where electronic components are cast with artificial resin (polyurethane) in an appropriately pre-formed casing. Our automated and CNC-controlled systems work very precisely, reliably and efficiently, so that we can even compete with low wage countries.

Why are electronic components cast?

1st Problem: Condensation / moisture

Electronics often come into contact with moist air or even water (rain). Casting / moulding electronic components offers the best possible protection against moisture.

2nd Problem: Electrical discharge

The challenge of placing as many functions as possible on the smallest possible circuit board (PCB), is sometimes not possible from the point of view of electrical discharge. However, the density of the artificial resin, makes it possible to produce a cast circuit board with the required minimum dimensions, and protect it from electrical discharges.

3rd Problem: Vibrations / Temperatures

Impacts and extreme temperatures reduce the life span of components, contacts and solder joints. Especially in the automotive industry, electronic components are often exposed to extreme conditions. Our casting process offers the best possible protection of your components against strong vibrations, and makes them resistant to temperatures from -40°C to +130°C.

4th Problem: Competition and manipulation

Casting electronic components not only protects your products against incorrect use or certain manipulations, but also the curious gaze of your competitors.